Executive Summary

As space commercialization accelerates, the imperative for versatile robotic manipulators becomes increasingly evident. This whitepaper examines how modular, intelligent robots—integrated with advanced autonomy software—can reduce operational costs, extend mission lifespans, and unlock new capabilities in orbit, on the Moon, and beyond. PickNik Robotics is at the forefront, defining the software infrastructure (MoveIt Pro and Space ROS™) essential for this next generation of robotic systems.

Introduction

The emergence of in-space manufacturing, satellite servicing, and lunar infrastructure heralds a new commercial era. However, the high costs associated with launching mass and utilizing astronaut time necessitate more efficient solutions. Robotic systems, particularly general-purpose manipulators, are pivotal in making space operations economically viable and scalable. This paper outlines the use cases for robotic manipulators and underscores the critical role of autonomy software in realizing their full potential.

Applications of Robotic Manipulators in Space

Fabrication in Microgravity

Robotics significantly enhances the feasibility of in-space fabrication. For instance, the production of optical fibers like ZBLAN benefits from microgravity, resulting in fibers with fewer imperfections, higher bandwidth, and reduced latency—advantages crucial for building the backbone of the internet and specialized applications like high-frequency trading.

Similarly, 3D printing of organic tissue in microgravity offers stability unattainable on Earth, although this technology remains at a lower readiness level compared to optical fiber production.

To scale up fabrication in microgravity, reliance on astronauts is impractical. Robots can efficiently transfer raw materials to fabrication sites and relocate finished products, performing repetitive and precise procedures over extended periods.

Routine Inspection, Maintenance, and Repair of Space Stations

Given the high value of astronaut time, delegating housekeeping and maintenance tasks to robots is advantageous. Robots can perform tasks like clean surfaces to prevent bacterial spread, inspect instrument panels, airflow, and detect chemical leaks, as well as perform basic repairs under remote supervision.

Servicing of Space Stations and Satellites

Traditionally, satellites were deployed as fixed assets with limited lifespans. Robotics now enables designs with serviceability and upgradeability in mind, allowing for more frequent updates to components like cameras and computational units without the need for extensive radiation hardening.

This shift permits the use of more advanced and cost-effective components, as radiation-hardened hardware often lags behind terrestrial counterparts in performance. General-purpose robots can extend the life of existing satellites through repairs, part replacements, and refueling. In the long term, robots may even recycle decommissioned satellites, addressing the growing issue of space debris.

Deployment of Large Structures: Space Telescopes and Solar Arrays

Currently, space telescopes and solar arrays often rely on complex, one-time-use self-assembly mechanisms, leading to lengthy technology maturation processes. Combining 3D printing in space with robotic assembly offers an alternative. Demonstrations like Redwire’s Archinaut system for NASA’s OSAM-2 mission show that deploying similar systems for different designs can be expedited, as most components have already been validated.

Robotics also enhance the serviceability of telescopes and solar arrays, allowing for the replacement of parts sent from Earth or 3D printed and assembled in orbit.

Construction of Lunar and Planetary Outposts

Designing self-assembling outposts presents significant challenges. While astronauts can assist, risks such as high radiation exposure limit their involvement. Robots can mitigate these risks by collecting lunar regolith to create building materials, assembling structures from these materials, and moving cargo autonomously from resupply missions.

The Case for a General-Purpose Space Robot

Developing flight-ready robotic systems is an expensive and time-consuming endeavor, with each component requiring rigorous testing to meet environmental, reliability, and safety standards. Creating a new robot for each task is economically unfeasible, especially when launch mass and budget constraints are considered.

A general-purpose robot offers a solution. By developing a single, flight-ready manipulator platform adaptable to multiple missions, space programs can significantly reduce the number of custom systems needing full certification. This approach allows for the amortization of development costs across various applications, such as orbital servicing, microgravity manufacturing, and lunar construction.

Standardized, modular robots supported by flexible autonomy software also reduce operational complexity and risk. They are easier to maintain, train for, and deploy repeatedly, thereby de-risking the path to scalable space operations. For example, PickNik is working with space enterprises like NASA and JAXA to standardize interoperable space robotics software via the Space ROS project - the Robot Operating System for Space.

Supervised Autonomy: Bridging Teleoperation and Full Autonomy

Advanced robotics software is essential for the functionality of general-purpose hardware in space. PickNik Robotics specializes in developing software for robot intelligence and autonomy.

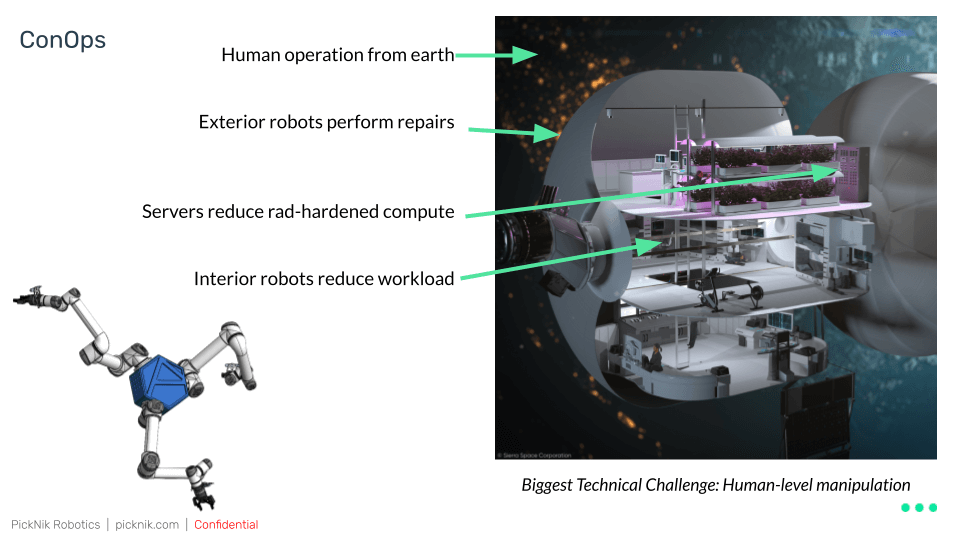

While full autonomy is the ultimate goal, current operations will likely involve human oversight to mitigate technical risks and bridge the trust gap between developers and space command teams. However, high latency between space-based robots and Earth-based operators makes traditional teleoperation inefficient.

PickNik has developed robotics software—partially funded by NASA and Space Force—that enables control of robotic manipulators over high-latency connections through supervised autonomy. This approach allows robots to perform tasks mostly autonomously, with operators providing varying levels of supervision as needed.

PickNik’s hardware-agnostic software integrates with various manipulators, offering a user-controllable sliding scale of autonomy—from manual teleoperation to full autonomy. As hardware and software capabilities advance, this software facilitates seamless transitions to more autonomous operations.

Currently, several modular space-rated robotic manipulators exist:

-

Tethers Unlimited’s KRAKEN® Arm: A compact, high-performance manipulator designed for in-space servicing and assembly operations. It features a modular design and integrates with the Robot Operating System (ROS) and MoveIt motion planning software.

-

Motiv Space Systems’ xLink™ System: A modular, adaptable robotic arm developed by the team behind NASA’s Mars 2020 Perseverance rover. xLink™ combines high-reliability spaceflight elements with cost-effective technologies, enabling rapid integration and deployment.

-

Redwire’s STAARK® Arm: An affordable, modular robotic system designed for various on-orbit applications. The STAARK® arm features customizable joints and links, allowing for easy adaptation to mission requirements and spacecraft constraints.

For a full list of commercially available space robotic arms, see this post.

PickNik is also developing two concepts for Intravehicular Activity (IVA) applications:

-

Arm-on-Rail Approach: Increases the robot’s workspace while maintaining low technical risk.

-

Three-Arm System: Two manipulators dedicated to locomotion (e.g., climbing handrails) and one for manipulation. This ambitious concept aims to advance the state of the art in space robotics by enabling robots to traverse and operate within spacecraft autonomously.

The Road Ahead

The next phase of space commercialization demands robotic systems that are flexible, autonomous, and intelligent. PickNik Robotics comprehends both the operational and technical challenges and is actively developing the software to transition from vision to deployment. Whether constructing orbital factories or lunar outposts, PickNik is the partner to help define your robotic concept of operations.

About PickNik Robotics

PickNik Robotics is a leading developer of robotic arm applications, offering cutting-edge software and services to automate complex tasks. Our flagship product, MoveIt Pro, is designed to help organizations achieve unprecedented efficiency and precision in their robotic operations. Founded in Boulder, Colorado, PickNik Robotics is committed to pushing the boundaries of what is possible in the field of robotics.